Electrical Troubleshooting

| How to |

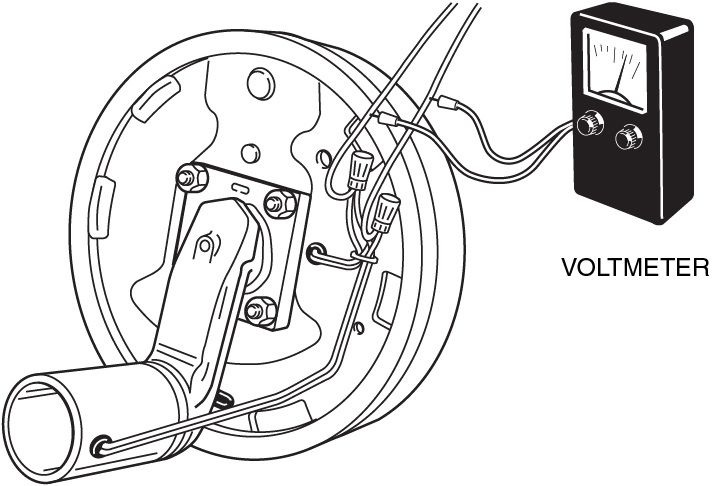

System voltage is measured from the magnets by connecting the voltmeter to the two magnet lead wires at any brake. This may be accomplished by using a pin probe inserted through the insulation of the wires dropping down from the chassis or by cutting the wires. The engine of the towing vehicle should be running when checking the voltage so that a low battery won't affect the readings.

Voltage in the system should begin at

The threshold voltage of a controller is the voltage applied to the brakes when the

controller first turns on. The lower the threshold voltage the smoother the brakes will operate. Too high of a threshold voltage (in excess of

| How to |

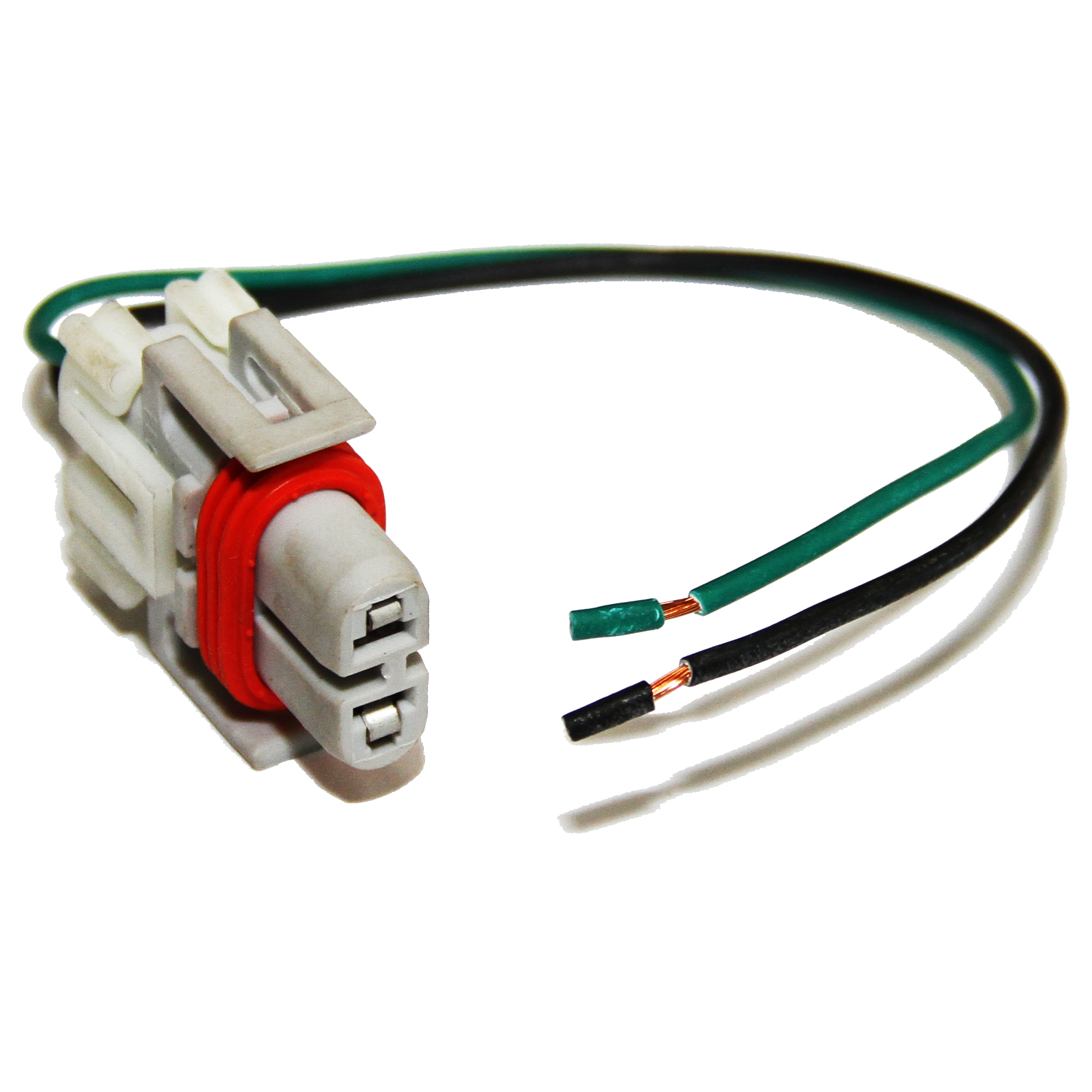

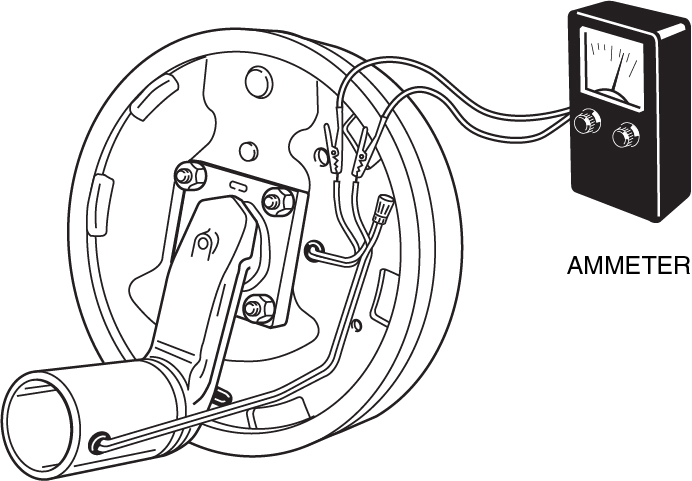

System amperage is the amperage being drawn by all brakes on the trailer. The engine of the towing vehicle should be running when checking amperage.

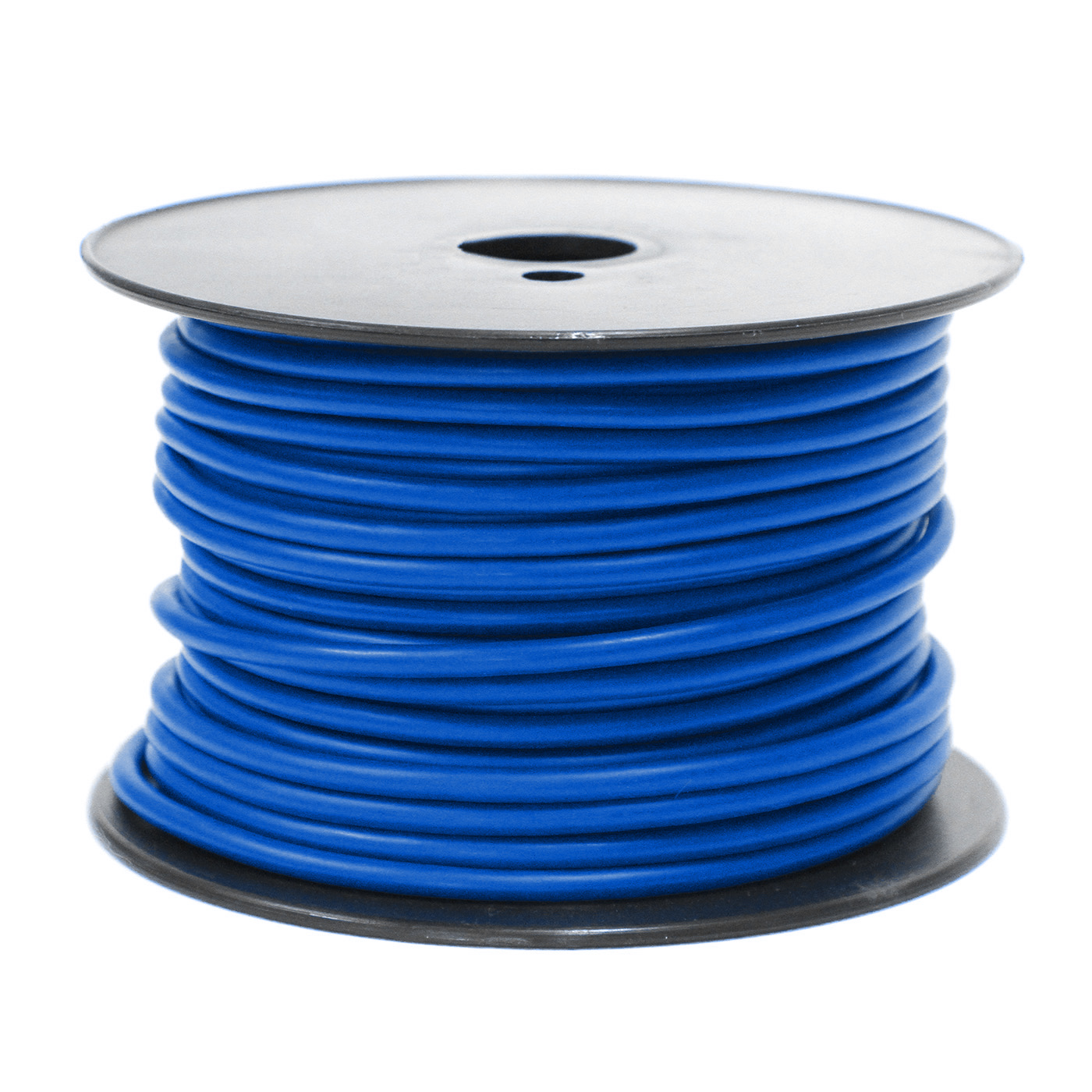

One place to measure system amperage is at the blue wire of the controller which is the output to the brakes. The blue wire must be disconnected and the ammeter put in series into the line. System amperage draw should be as noted in the following table. Make sure your ammeter has sufficient capacity and note polarity to prevent damaging your ammeter.

If a resistor is used in the brake system, it must be set at zero or bypassed completely to obtain the maximum amperage reading. Individual amperage draw can be measured by inserting the ammeter in the line to the magnet you want to check. Disconnect one of the magnet lead wire connectors and attach the ammeter between the two wires. Make sure that the wires are properly reconnected and sealed after testing is completed.

| The Most Common |

| Problems | Common causes |

| Low or no voltage and amperage at the brakes |

|

| Shorted or partially shorted circuits |

|

Finding the system short is a matter of isolation. If the high amperage reading drops to zero by unplugging the trailer, then the short is in the trailer. If the amperage reading remains high with all the brake magnets disconnected, the short is in the trailer wiring.

All electrical troubleshooting procedures should start at the controller. Most complaints

regarding brake harshness or malfunction are traceable to improperly adjusted or non-functioning controllers. See your controller manufacturer’s data for proper adjustment and testing procedures. If the voltage and amperage aren’t satisfactory, proceed on to the connector and then to the individual magnets to isolate the problem source.

If in doubt, Frameco strongly recommends that all maintenance and repair work be performed by qualified and competent professionals, such as your trailer manufacturer.